AC power supplies, manufactured by Basafan Company are designed in various frequency bands, as single-frequency or covering specific frequency ranges with a wide range of power and voltage. The various models of this product are listed in the following table:

Models and Specifications

| Model | Frequency Range | Specifications |

| LF-WB 800 V | DC-300 KHz wideBand | 0-800 volts peak-to-peak, 100 mA, capable of generating various waveforms, fully linear output, short-circuit, over-load, over-voltage and over-temperature protection |

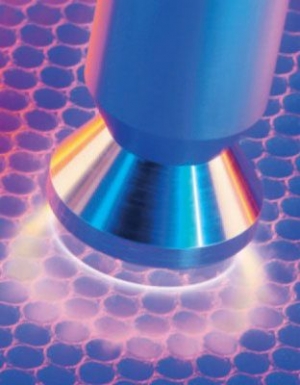

| LF-HV | Up to 100 KHz | Up to 25 kV voltage, single frequency or covering specific frequency ranges, up to 5 kW power. |

| LF-PU | Up to 100 Khz | Pulsed output, up to 1000 V, generating positive and negative pulse, negative and positive peak pulse can be tuned independently |

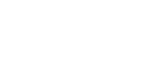

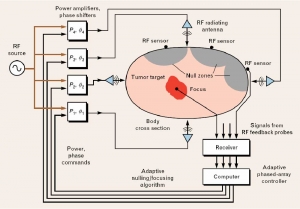

RF-HP | 2, 13.56, 27.12, 40.86 MHz, or customized frequency | Available in different capacities (up to 15 kW with semiconductor and up to 100 kW with vacuum lamp). With forward and reflected power display, reflected power limiter, closed-loop power control, impedance matching network. |

RF-WB | 2-30 MHz 20-60 MHz or customized frequency ranges | Available in various customized capacities, with forward and reflected power display, reflected power limiter, closed-loop power control, linear output. |

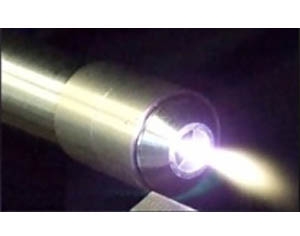

| MW-HP | 2.45 GHz | Available up to 6 kW, with launcher accessories, circulator, waterload, directional coupler, stub tuner, power supply and closed loop microwave power control. |