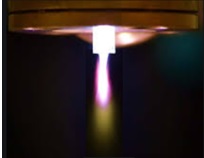

The corona plasma torch is a system used for the processing of two- and three-dimensional polymeric surfaces. This plasma is created under atmospheric pressure by applying an alternating voltage with a frequency of several tens of thousands of kilohertz between two electrodes. This device is used for increasing the printability of three-dimensional polymeric and metallized parts.

Creating or increasing the Nanoscale surface roughness is among the features of this process. It is expected in this state that the wetting and color absorption qualities of fabric surfaces increase. Also, the presence of an active surface layer significantly improves the adhesion of coatings and Nano-layers by creating bonds at the atomic level.

The plasma torch system can be used for increasing printability, improving the absorption and stability of printing ink, labelling, and improving surface adhesion in various surfaces.

In summary, the advantages of using corona plasma are as follows:

- Uniform and smooth activation of surfaces even in three-dimensions

- Rapid activation of surfaces and the possibility of use for large dimensions

- Processing of openings and complicated surfaces in three-dimensional objects

- Changing surface characteristics without changing volumetric characteristics

- Economy and durability of adhesion characteristics

- Environmental friendliness

Features and Capabilities

Output power: 600W

Torch dimensions: 3cm by 6cm with a length of more than 5cm

Optimal working voltage and frequency peaks for producing the appropriate atmospheric corona plasma for making polymeric surfaces hydrophilic

With an atmospheric plasma torch connected to the generator via a cable

No requirement for applying a gas flow to the torch (capability of applying a combined nitrogen-argon gas flow or any other gas)

Atmospheric working pressure

Short-circuit and overtemperature protection and arc management system

Compressed air cooling (internal fan)

Power supply: 220V